The WMW Series Aqueous-Based Manual Parts Washing Cabinet is the most cutting-edge cleaning system available on the market today. These cabinets offer increased operator comfort with ergonomic working height, heatable cleaning fluid and easy operation and maintenance for manually washing various-sized parts with cleaning solvent in safe work environments.

WMW Series Solvent Washing Cabinets are made of durable industrial-grade steel or optional stainless steel. Washing fluid circulates in a loop in a pneumatically system and can be reused over and can be heated to desired temperature, thanks to heating elements integrated to the tank. Circulating debris are trapped in a filtration system integrated to the pump.

This line of cleaning cabinets is available in different sizes and configurations in order to achieve desired performance for washing parts in any shapes and sizes, without any abrasive that could damage precision machined parts.

Key features of this system

- Quick heat time

- Well-lit cabinet with clear visibility

- Flexible neoprene gloves

- Ergonomic working height

- Versatile and practical washing accessories

- Adjustable flow pressure

3 choices of feeding systems

Choose from 3 feeding systems according to desired result and application:

- High-Pressure Jet WMW-HP

High-pressure jet system powered by electric pump pushes cleaning fluid towards cleaning accessories with pressure ranging from 0 to 3,000 psi. Operator manually activates cleaning accessories by pressing trigger or flipping switch.

- Low- Pressure Jet WMW-LP

Low-pressure jet system is similar to high-pressure, but is equipped with diaphragm pump that achieves 30 to 100 psi.

- Suction-Type Vaporization System WMW-S

Contrary to pressure jet systems, suction-type vaporization systems operate using the Venturi principle, sucking fluid from cleaning accessories. Liquid output in wide-spray jet covers large section of part that needs cleaning, with air added to dislodge hard-to-remove oil and grease. Cleaning accessories activated with foot treadle.

Standard Features

- Choice of feeding system: high-pressure pump, low-pressure pump or suction-type

- Large side door for easy loading

- Safety door switch stops pump if door is open

- Work Shelf made of 3/8″ thick perforated polypropylene

- Air blow-off nozzle for parts drying

- 500 lb load capacity.

Optional Features

- 14-gauge 304 stainless steel construction

- Higher PSI pump – up to 3,000 PSI

- Heating element integrated in pump to heat cleaning fluid up to 120°F (49°C)

- Rinse with clean fluid and tank overflow sensor

- Turntable

- Tiltable tabletop

- Stainless steel tank located beneath washer, with side door to verify fluid level and wheels for easy maintenance

- Front opening door for complete access to work surface

- Front door security system stops door from closing when object is detected

- Filling pump

- Retractable floor for easier loading/unloading procedures

Take a Look

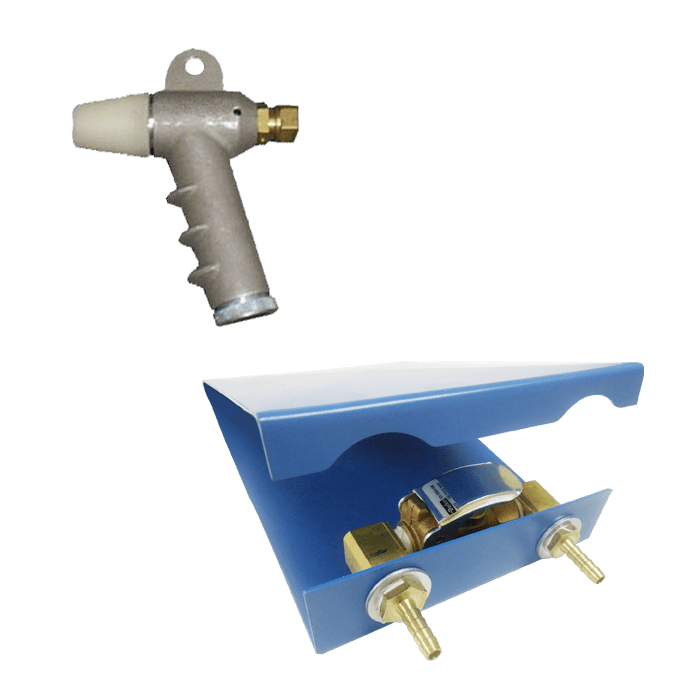

Optional Cleaning Accessories

Trigger Spray Gun

Air Blow Gun

Precision Manual Flow-Through Brush

Suction-Type Spray Gun Activated by Treadle*

*Available with Suction-Type Vaporization System only

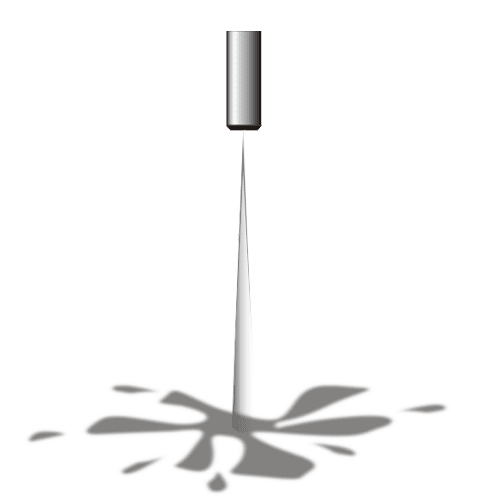

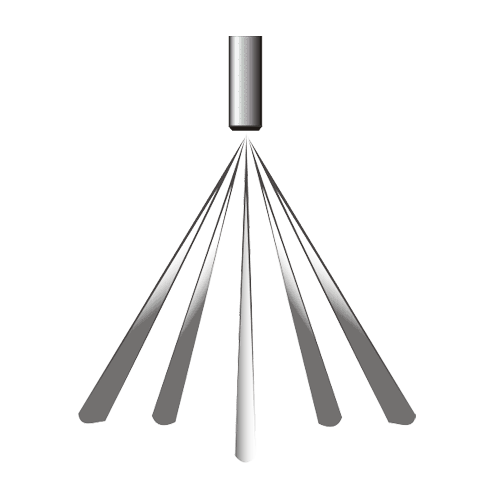

Available Jet Nozzles

Splash Spray Pattern

Multiple Stream

Flat

Hollow Cone

Full Cone

Square

Why choose IST Pure Heavy-Duty Industrial Parts Washers?

- Heavy-Duty Construction: Built with industrial-grade, corrosion-free materials that can withstand harsh industrial applications and heavy parts load

- Wide Variety of Cleaning Methods: Ultrasonic tanks, rotary table washers, agitating tanks, manual wash cabinets, immersive tanks, spray wash cabinets

- Versatility: Can be designed to work with cleaning solvent or aqueous-based soaps

- Customizable: Customized systems can be drawn to meet your specifications and exceed your expectations